DESCRIPTION:

A Drop In Anchor, also known as a machine screw anchor or a concrete anchor, is a type of fastener used to secure objects to concrete or other hard surfaces. It is commonly used in construction and industrial applications where a strong and secure connection to concrete is needed.

Other names: Concrete Drop In Anchor, Concrete Anchors, machine screw anchor, concrete anchor bolts, concrete anchor screws, drop in anchor for concrete

STRUCTURE:

A Drop-In Anchor consists of several key components that work together to secure objects to a concrete or masonry surface. Here is a breakdown of its typical structure:

- Threaded Body: The main part of the Drop-In Anchor is a cylindrical body with internal threads. This threaded body is made from metal, such as steel or stainless steel, and is typically hollow.

- Expanding Sleeve: Inside the threaded body, there is a tapered or conical expanding sleeve. This sleeve is usually made of metal or plastic. When the Drop-In Anchor is installed, the expanding sleeve is forced outward, creating a tight grip against the sides of the hole in the concrete.

- Lip or Flange: The top of the Drop-In Anchor typically features a lip or flange. This lip provides a stop for the setting tool and prevents the anchor from falling into the hole during installation.

- Internal Threads: The internal threads within the threaded body are designed to accept a bolt, threaded rod, or other fastener. The size and thread type of these internal threads must match the fastener being used.

- Bottom Plug or Stop: At the bottom of the Drop-In Anchor, there is often a plug or stopper. This component prevents the expanding sleeve from being pushed through the anchor during installation.

- Rim or Grooves: Some Drop-In Anchors may have a rim or grooves on the exterior of the threaded body to improve the anchor’s grip in the concrete.

- Corrosion Resistance Coating: Depending on the application and material, Drop-In Anchors may have a corrosion-resistant coating or finish to protect them from rust and deterioration when used in outdoor or corrosive environments.

The structure of a Drop-In Anchor is designed to work in tandem with the installation process. When the anchor is properly installed by inserting it into a pre-drilled hole and using a setting tool to strike the top, the expanding sleeve expands and grips the concrete tightly, creating a secure and reliable anchor point for fasteners.

The threaded body allows for the attachment of bolts, threaded rods, or other hardware to secure objects to the anchor. Proper installation is crucial to ensure the anchor’s effectiveness and load-bearing capacity.

WORKING:

Here’s how a Drop-In Anchor typically works:

- Installation: A hole is drilled into the concrete or masonry surface using a masonry bit of the appropriate size. The hole’s depth and diameter should match the specifications provided for the specific Drop-In Anchor being used.

- Insertion: The Drop-In Anchor is then inserted into the hole with the threaded portion facing up.

- Setting: A setting tool, often a setting punch or setting tool kit, is used to tap the top of the Drop-In Anchor, causing it to expand and grip the sides of the hole tightly.

- Attachment: Once the Drop-In Anchor is properly set, a bolt or threaded rod can be threaded into it. This allows for secure attachment of various objects to the concrete surface.

The Drop-In Anchor is designed to provide a strong and reliable anchoring point in concrete, block, or other hard materials. It is commonly used for installing handrails, machinery, equipment, or other fixtures that need to be firmly attached to a concrete surface. It’s important to choose the appropriate size and type of Drop-In Anchor for your specific application to ensure a reliable and secure connection.

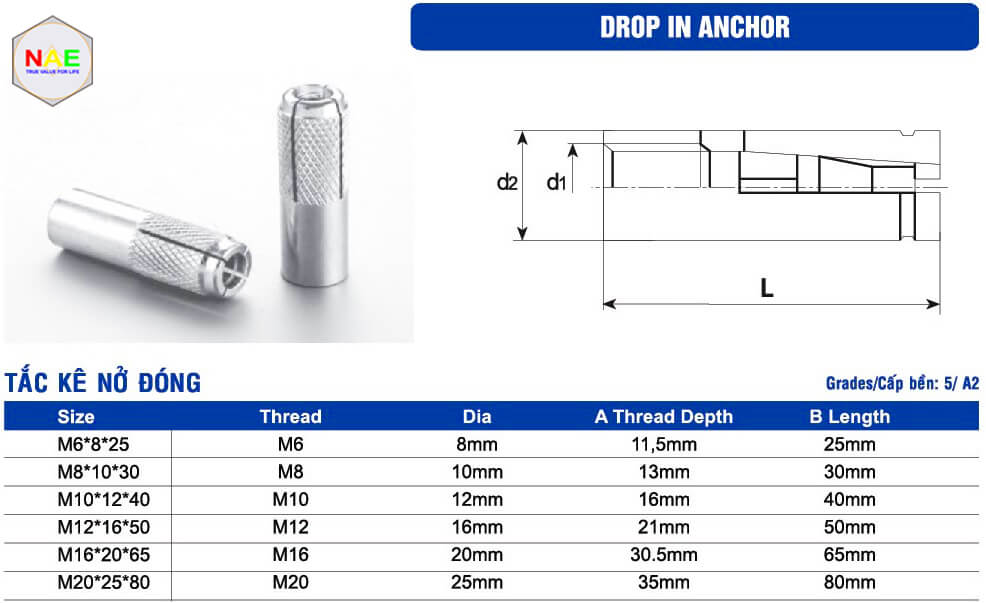

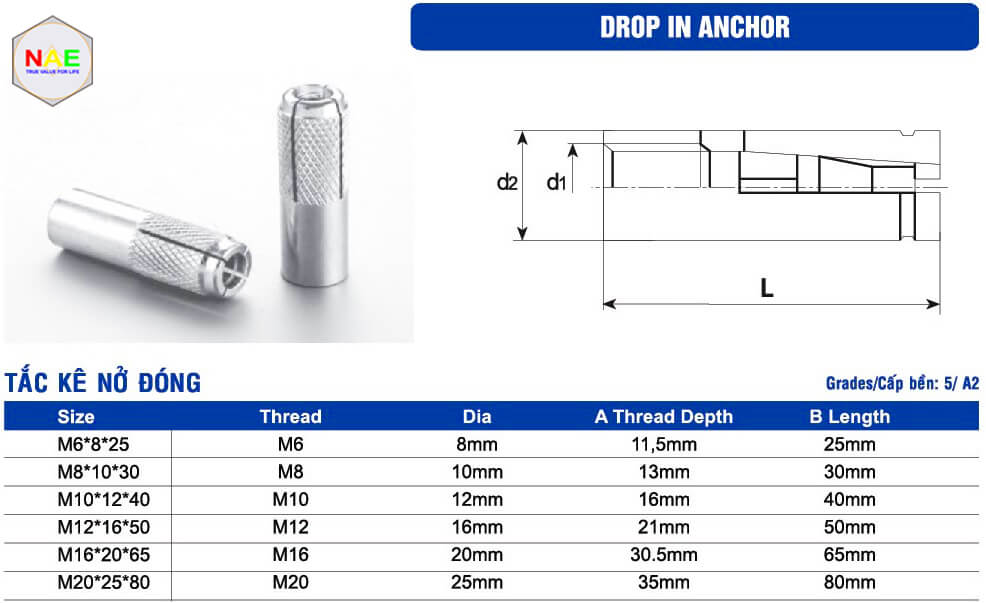

SPECIFICATIONS:

- Diameter (M): M6-> M20 mm

- ISO Grade: 8/ 5.6/ 6.8/ 8.8/ 10.9/ 12.9

- Material: Carbon steel ; Stainless steel 316/304/201

- Surface Finish: Black (plain/black); Electro-zinc-plated, Hot dip galvanized, Dacromet plated, Stainless steel 316/304/201

DIMENSIONS:

PRODUCT IMAGES:

CONTACT INFO:

NAM AN INDUSTRIAL MATERIAL COMPANY LIMITED

Warehouse/Office address: No. 68, Van Canh Service Land, Hoai Duc District, Ha Noi City, Viet Nam.

Factory address: National Highway 5, Quy Duong, Tan Truong Commune, Cam Giang District, Hai Duong, Vietnam.

Hotline/Zalo: 0941 636 369 – 0983 344 163 – 0983 506 389

Email: Bulongocvitnaman@gmail.com

Website: https://en.bulongnaman.vn/

Youtube Channel: https://www.youtube.com/channel/UCVF6aCJCm1IiZABqXE2_KMw

No. 68, Van Canh Service Land, Hoai Duc District, Ha Noi City, Viet Nam.

No. 68, Van Canh Service Land, Hoai Duc District, Ha Noi City, Viet Nam. bulongocvitnaman@gmail.com

bulongocvitnaman@gmail.com