DESCRIPTION:

A slip pin, also known as a cotter pin or cotter key, is a fastener used to secure two components together in a way that allows for easy disassembly.

STRUCTURE:

A slip pin typically consists of the following components:

- Tapered Shaft: The main body of the cotter pin is a tapered shaft, which is usually cylindrical in shape. This shaft has a pointed or rounded end, making it easier to insert through holes in components.

- Split End: One end of the cotter pin is split into two legs that can be bent outward. This split end allows the pin to be inserted into holes in the components, and when the legs are bent apart, they prevent the pin from easily slipping back out.

- Two Legs: The split end of the cotter pin forms two legs that extend from the split point towards the opposite end. These legs are typically parallel to each other before bending.

- Head: The opposite end of the cotter pin often has a head or larger diameter section. This head serves as a stopper to prevent the cotter pin from passing completely through the hole.

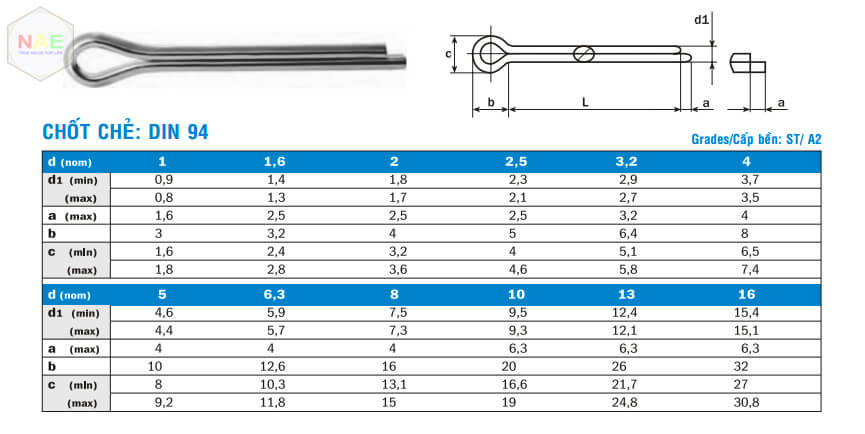

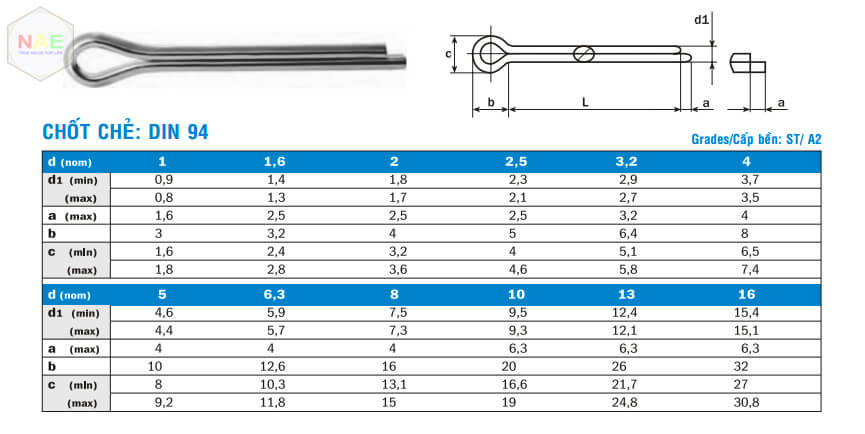

SPECIFICATIONS:

- Diameter (M): 1 – 16 mm

- ISO Grade: 8/ 5.6/ 6.8/ 8.8/ 10.9/ 12.9

- Material: Carbon steel ; Stainless steel 316/304/201

- Surface Finish: Electro-zinc-plated, Hot dip galvanized, Dacromet plated, Stainless steel 316/304/201

- Standard: DIN 94

DIMENSIONS:

APPLICATIONS:

Slip pins, have various applications across different industries and scenarios. Their primary purpose is to secure two or more components together in a way that allows for easy disassembly when needed. Here are some common applications of cotter pins:

- Automotive Industry: Slip pins are used to secure various automotive components, including brake components, suspension parts, and steering components. For example, they might be used to secure castle nuts on tie rod ends or ball joints.

- Construction and Machinery: In construction and heavy machinery, cotter pins are often used to secure bolts, nuts, and pins in place. This ensures that critical connections remain intact, even in high-vibration environments.

- Agricultural Equipment: Slip pins are used in farm machinery to secure parts like PTO shafts, hitch pins, and various linkage components. They provide a reliable way to prevent unintentional disconnection.

- Marine Applications: In boats and ships, cotter pins are used to secure rigging components, anchor hardware, and other critical connections. They are particularly useful in saltwater environments due to their corrosion resistance.

- Aerospace: In the aerospace industry, cotter pins are used for various purposes, such as securing fasteners in aircraft components and control systems.

- Bicycles and Sports Equipment: Cotter pins are used in the assembly and maintenance of bicycles and other sports equipment, ensuring that parts like pedals and wheels stay securely attached.

- Furniture and Household Items: On a smaller scale, cotter pins can be used in DIY furniture assembly or to secure parts of household appliances and gadgets.

- Locking Hitch Pins: In trailer hitch assemblies, cotter pins or similar locking hitch pins are used to secure the hitch ball to the receiver and keep trailer couplers or accessories in place.

- Farm and Gardening Equipment: Slip pins are used in the assembly of farming and gardening equipment, such as plows, tillers, and rotary cutters.

- Emergency Repair: Cotter pins are sometimes used in emergency field repairs to secure components temporarily until proper repairs can be made.

Cotter pins are valued for their simplicity, reliability, and ease of use. They provide a cost-effective way to secure connections while still allowing for quick disassembly and maintenance, making them a versatile and widely used fastening solution in various industries.

PRODUCT IMAGES:

CONTACT INFO:

NAM AN INDUSTRIAL MATERIAL COMPANY LIMITED

Warehouse/Office address: No. 68, Van Canh Service Land, Hoai Duc District, Ha Noi City, Viet Nam.

Factory address: National Highway 5, Quy Duong, Tan Truong Commune, Cam Giang District, Hai Duong, Vietnam.

Hotline/Zalo: 0941 636 369 – 0983 344 163 – 0983 506 389

Email: Bulongocvitnaman@gmail.com

Website: https://en.bulongnaman.vn/

Youtube Channel: https://www.youtube.com/channel/UCVF6aCJCm1IiZABqXE2_KMw

No. 68, Van Canh Service Land, Hoai Duc District, Ha Noi City, Viet Nam.

No. 68, Van Canh Service Land, Hoai Duc District, Ha Noi City, Viet Nam. bulongocvitnaman@gmail.com

bulongocvitnaman@gmail.com

admin –

A slip pin, also known as a cotter pin or cotter key, is a fastener used to secure two components together in a way that allows for easy disassembly.